What’s The Best Wood To Manufacture Outdoor Business Signage

When it comes to business signage, choosing the best wood ensures your sign will last years and retain its original lustre, but which wood material is the best for manufacturing outdoor signs?

Best materials for making outdoor wooden signage

There are several wooden materials that most sign companies use to build custom outdoor signage, but the following are the most common:

- Water-proof plywood (Crezon board)

- Redwood (natural wood)

- Cedar wood (natural wood)

- HDU (high-density urethane) foam (wood substitute)

Crezon board (water-proof plywood)

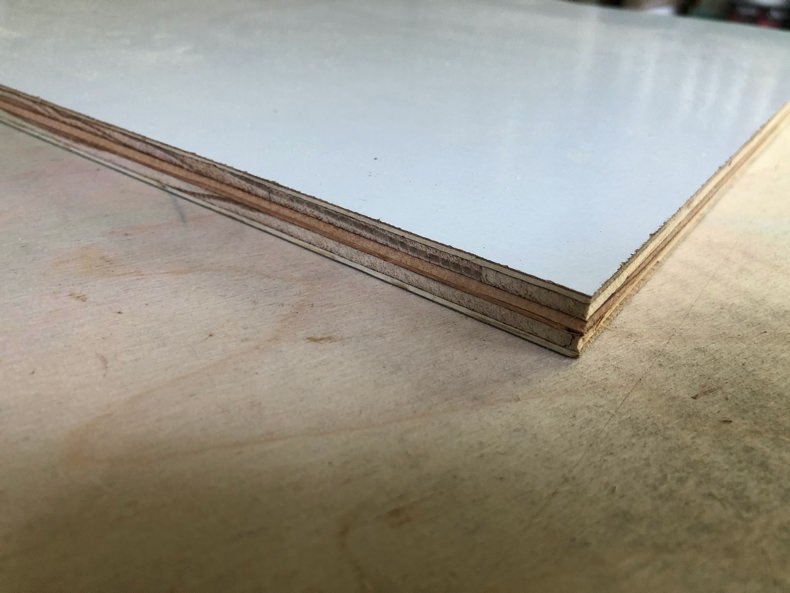

Depending on the application, the most commonly used wood for outdoor signage would be Crezon board (water-proof plywood). Crezon plywood has a substrate surface which you apply vinyl graphics or paint, and has outstanding outdoor durability.

Depending on the application, the most commonly used wood for outdoor signage would be Crezon board (water-proof plywood). Crezon plywood has a substrate surface which you apply vinyl graphics or paint, and has outstanding outdoor durability.

Crezon plywood has an extremely smooth surface, and is great for real estate signs, and other outdoor business street signage.

Other types of wood can be used but require some form of extra protection applied to them to protect them from the harsh elements like sun UV exposure, moisture and harsh cold weather conditions.

HDU (high-density urethane) Foam – Wood Substitute

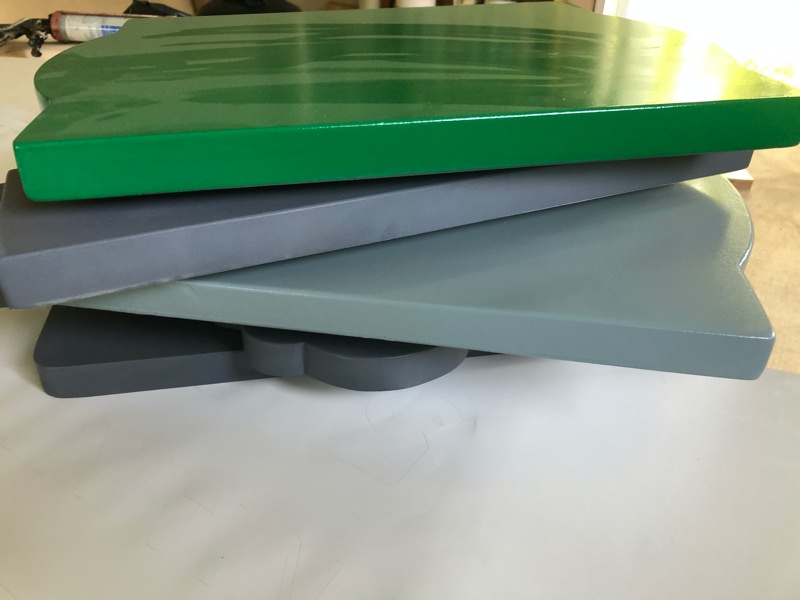

The second most common material used for outdoor business signage are HDU foam as a wood substitute.

HDU foam is a great wood substitute and is highly durable and repairable, and a very weather-resistant product which is eco-friendly because it’s made from recycled materials.

HDU foam is a great wood substitute and is highly durable and repairable, and a very weather-resistant product which is eco-friendly because it’s made from recycled materials.

HDU foam is much easier to work with, and less expensive. It can be re-painted, re-finished and easily repaired. HDU foam is readily available, especially when other forms of wood like cedar wood and Redwood are not available due to seasonal shortages and other unforeseen circumstances.

HDU foam is much lighter than natural wood, more durable, easier to install, and lasts up to ten years longer than wood because it’s much less prone to failure. Wood generally fails over a shorter time because strips of wood which are glued together eventually come apart. A good way to explain this is by thinking of what would happen if you soaked your wood cutting-board in water for a a few weeks. Eventually the glue-bond that keeps the small pieces of wood together would deteriorate and the wood pieces would start to separate.

Redwood & Cedar Wood (natural wood)

Redwood and cedar wood are a natural source fibre material and because of the oils contained within them, they easily resist the elements and extreme weather conditions for many years. Red and cedar wood are also considered soft wood, and make carving into quite easy which allows for more accuracy during the design process.

Redwood and cedar wood are a natural source fibre material and because of the oils contained within them, they easily resist the elements and extreme weather conditions for many years. Red and cedar wood are also considered soft wood, and make carving into quite easy which allows for more accuracy during the design process.

Redwood and cedar wood have one of the best outdoor weathering capabilities. The wide growth-rings give this wood the desired affect that most sign-makers and buyers are looking to achieve.

Cedar and Redwood from natural sources are becoming scarce and harder to source which is driving up the cost of wood signs manufactured with these products, and making the manufacturing process more expensive.

CNC and Sand-blasting Signage

When CNC or sand-blasting custom outdoor wood signage, HDU foam, Redwood and cedar wood are the best materials for this type of application.

Although popular, environmental issues have hindered the use of Redwood and cedar, making them an expensive choice. Blanks have to be glued together with the edge-grain facing outwards, in order to achieve a clean and sharp appearance. The joints where the blanks are assembled and glued together do last a long time, but are also prone to delamination from each other, after a few years of exposure depending on the location of the sign and other environmental factors.

Cedar and Redwood are also quite heavy and require extra support when mounting.

Another disadvantage of using cedar or Redwood blanks for sand-blasting, is that the density is not always consistent across the whole board. This makes it more difficult to achieve a uniformity of depth. Some areas which are more dense may not carve out as accurately and effortlessly as other less dense areas of the wood blank (e.g. wood knots).

Another disadvantage of using cedar or Redwood blanks for sand-blasting, is that the density is not always consistent across the whole board. This makes it more difficult to achieve a uniformity of depth. Some areas which are more dense may not carve out as accurately and effortlessly as other less dense areas of the wood blank (e.g. wood knots).

HDU foam is probably the best material to use for sand-blasted or CNC signage because it comes in one piece and there is a complete uniformity of depth when it comes to carving the design into the material.

Outdoor Wood Signage Uses

Wooden signs are a great choice for the following types of signage, but not limited to:

- camping signs

- directional signs

- open and close signs

- social distancing signage

- camp ground signs

- real estate signage

- golf course signage

- cottage signs

- farm signs

- outdoor business signage

- anything else you can think of

Each material has it’s own benefits and drawback and in order to determine which product is best for your use, talk to your local sign shop. They’ll be able to give you all the details related to your situation and recommenced the best material to use for your particular situation.